Automatic Backwash Water Screen Filter for Industrial Circulating Water

Basic Info

Model No.: XLQ

Product Description

Model NO.: XLQ Usage: Environmental Protection, Chemical Industry Style: Vertical Certification: ISO SGS Install: Vertical, Horizontal Pressure Loss: 0.01-0.08mpa Backwash Time: 60-120 Seconds Power: 380, 50Hz, 3 Phase, Controller 220V Certificates: ISO9000, SGS Specification: ISO9001: 2008 HS Code: 8421299090 Type: Water Filter Motive Force: Electric power Performance: Efficient Filtration Material: Carbon Steel, 304ss or 316L Filter Precision: 50-500 Microns Max Pressure: 1.0-1.6mpa Backwash Water Consumption: About 500 Kg Motor: 14-20 Round Every Minute Trademark: PEIDE Origin: China Automatic Backwash Water Screen Filter for Industrial Circulating Water (XLQ)

1.Features: 1.Small volume, low cost, no filter, a small amount of maintenance. Long mesh tube network life and high reliability. 2.High degree of automation, easy operation and management, long-term unattended operation. 3. Low pressure loss, energy saving, the use of the main channel hydraulic backwash, no need for backwash water. 4. Filtration precision: 1000-5000μm. 5. Easy to install, can be installed directly on the pipe, particularly suitable for field use under various process conditions. 6. Widely usage, ensure a safe operation of the water utility, simple and reliable method in any backwash process, can maintain uninterrupted normal operation. 2.Applications:

1. The domestic water supply, water supply and pre-filtering for industrial water supply; 2. steel, petroleum, chemical, paper, automotive, food, metallurgy and other industries beginning circulating water filtration; 3. Fist stage of circulating cooling water filtration; 4. The water reuse, waste Water Treatment filter; 5. Central air conditioning, boiler return early filter; 6. Municipal, green spraying, irrigation, agricultural irrigation, drip Irrigation water filter early.

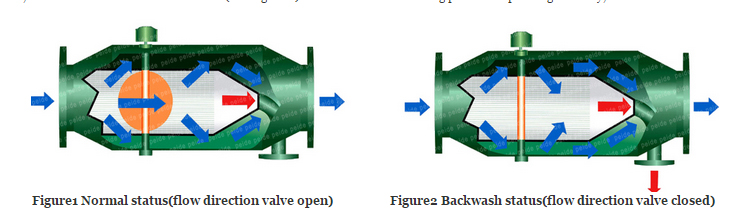

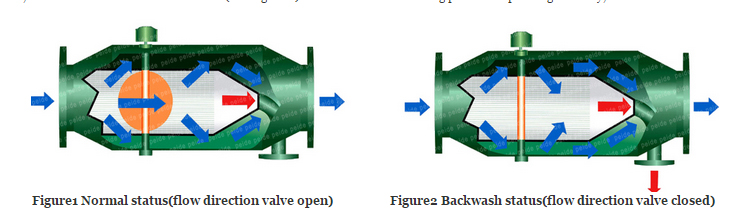

3.Structure and Working Principle

P-type automatic sewage filter is made of high-quality carbon steel cylinder, the special structure of the stainless steel wedge filter screen, flow direction valve and sewage drain. In the working status, flow direction valve is on, the water flow from the inlet into the filter, through the filter screen to the outlet (see Figure 1). When the filter needs sewage, flow direction valve closed, open the drain valve, water flows through the first half of the mesh filter, part of the water flow into the system from the outlet, the remaining water flow from the backside of the filter into the inside, automatic backwash the filter screen (see Figure 2). So that the entire washing process is operating normally, without downtime. Flow direction valve opening mechanism include sub-manual and electric type, when using an electric opening mechanism with clock control electrical control box, it can set the time required to achieve automatic cleaning sewage, then the outfall installed electric ball valves, flow direction valve and sewage electric valve to achieve linkage.

P-type automatic sewage filter is made of high-quality carbon steel cylinder, the special structure of the stainless steel wedge filter screen,electric actuator and sewage drain. In the working status,electric actuator is on, the water flow from the inlet into the filter, through the filter screen to the outlet (see Figure 1). When the filter needs sewage, butterfly valve closed, open the drain valve, water flows through the first half of the mesh filter, part of the water flow into the system from the outlet, the remaining water flow from the backside of the filter into the inside, automatic backwash the filter screen (see Figure 2). So that the entire washing process is operating normally, without downtime.

P-type automatic sewage filter is made of high-quality carbon steel cylinder, the special structure of the stainless steel wedge filter screen,electric actuator and sewage drain. In the working status,electric actuator is on, the water flow from the inlet into the filter, through the filter screen to the outlet (see Figure 1). When the filter needs sewage, butterfly valve closed, open the drain valve, water flows through the first half of the mesh filter, part of the water flow into the system from the outlet, the remaining water flow from the backside of the filter into the inside, automatic backwash the filter screen (see Figure 2). So that the entire washing process is operating normally, without downtime.

4.Parameter

4.Parameter

Single flow rate:15-900m³/h

The least working pressure:2.5bar

The highest working pressure:10-16bar(optional)

The pressure loss of cleaning:0.1-0.8bar

The highest temperature of working:70

The water consumption of self-cleaning one time:1% of all water flow

Filter precision:80-500 microns

cleaning method:sucking type

Cleaning time:35-90seconds

Connect method: flange

Drain diameter:50-80mm

Install Direction:vertical and horizontal

Control panel show method:LCD

Certificates

Welcome to inquire,We will offer you the best items! Contact us if you need more details on Water Filter. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Filter、Water Filter System. If these products fail to match your need, please contact us and we would like to provide relevant information.

1.Features: 1.Small volume, low cost, no filter, a small amount of maintenance. Long mesh tube network life and high reliability. 2.High degree of automation, easy operation and management, long-term unattended operation. 3. Low pressure loss, energy saving, the use of the main channel hydraulic backwash, no need for backwash water. 4. Filtration precision: 1000-5000μm. 5. Easy to install, can be installed directly on the pipe, particularly suitable for field use under various process conditions. 6. Widely usage, ensure a safe operation of the water utility, simple and reliable method in any backwash process, can maintain uninterrupted normal operation. 2.Applications:

1. The domestic water supply, water supply and pre-filtering for industrial water supply; 2. steel, petroleum, chemical, paper, automotive, food, metallurgy and other industries beginning circulating water filtration; 3. Fist stage of circulating cooling water filtration; 4. The water reuse, waste Water Treatment filter; 5. Central air conditioning, boiler return early filter; 6. Municipal, green spraying, irrigation, agricultural irrigation, drip Irrigation water filter early.

3.Structure and Working Principle

P-type automatic sewage filter is made of high-quality carbon steel cylinder, the special structure of the stainless steel wedge filter screen, flow direction valve and sewage drain. In the working status, flow direction valve is on, the water flow from the inlet into the filter, through the filter screen to the outlet (see Figure 1). When the filter needs sewage, flow direction valve closed, open the drain valve, water flows through the first half of the mesh filter, part of the water flow into the system from the outlet, the remaining water flow from the backside of the filter into the inside, automatic backwash the filter screen (see Figure 2). So that the entire washing process is operating normally, without downtime. Flow direction valve opening mechanism include sub-manual and electric type, when using an electric opening mechanism with clock control electrical control box, it can set the time required to achieve automatic cleaning sewage, then the outfall installed electric ball valves, flow direction valve and sewage electric valve to achieve linkage.

P-type automatic sewage filter is made of high-quality carbon steel cylinder, the special structure of the stainless steel wedge filter screen,electric actuator and sewage drain. In the working status,electric actuator is on, the water flow from the inlet into the filter, through the filter screen to the outlet (see Figure 1). When the filter needs sewage, butterfly valve closed, open the drain valve, water flows through the first half of the mesh filter, part of the water flow into the system from the outlet, the remaining water flow from the backside of the filter into the inside, automatic backwash the filter screen (see Figure 2). So that the entire washing process is operating normally, without downtime.

P-type automatic sewage filter is made of high-quality carbon steel cylinder, the special structure of the stainless steel wedge filter screen,electric actuator and sewage drain. In the working status,electric actuator is on, the water flow from the inlet into the filter, through the filter screen to the outlet (see Figure 1). When the filter needs sewage, butterfly valve closed, open the drain valve, water flows through the first half of the mesh filter, part of the water flow into the system from the outlet, the remaining water flow from the backside of the filter into the inside, automatic backwash the filter screen (see Figure 2). So that the entire washing process is operating normally, without downtime.  4.Parameter

4.ParameterSingle flow rate:15-900m³/h

The least working pressure:2.5bar

The highest working pressure:10-16bar(optional)

The pressure loss of cleaning:0.1-0.8bar

The highest temperature of working:70

The water consumption of self-cleaning one time:1% of all water flow

Filter precision:80-500 microns

cleaning method:sucking type

Cleaning time:35-90seconds

Connect method: flange

Drain diameter:50-80mm

Install Direction:vertical and horizontal

Control panel show method:LCD

| Max Water Temperature | 70 centigrade (Reach 100 centigrade in special requirements) |

| Filter precision | 80-500microns |

| Pressure loss | 0.01-0.08Mpa |

| Max pressure | 1.0Mpa, 1.6Mpa |

| Control method | Pressure differential control, time control and manual control |

| Filter flow | 15-1000 CMB/Hour. If customer need higher flow, we suggest using many automatic sucking type filter parallel. |

| Backwash Time | 60-120 seconds |

| Backwash Water Consumption | About 500 kg |

| Power | 380.50Hz, 3 phase, Controller 220V |

| Power of Motor | Suction type 0.37Kw |

| Motor | 14-20 round every minute |

| Filter chamber material | Resin covering carbon steel or stainless steel |

| Filter strainer | 316 stainless steel (weave, stintering, wedges) |

Certificates

Welcome to inquire,We will offer you the best items! Contact us if you need more details on Water Filter. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Filter、Water Filter System. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Self-cleaning filter > Applied for industrial recycle water

Premium Related Products

Other Products

Hot Products

oil-water juice water uv container price listuv plant disinfection system for waste water low priceUVC stainless steel disinfection machine best buywaste water treatment ozone generator stainless steel filter housing price liststeel cartridge automatic backwash filter254nm SS 304/316 UV sterilizer for food processmytest mini modernhome use water molten salt furnace for distillationBest Seller Suppliers antique bulk distilled waterantique dental water distiller best priceultraviolet sterilizer for water uv water disinfection systems uv technology for water purificationuv light water filter ultraviolet sterilizer uv light water purificationfish tank sterilizer ultraviolet light for wateruv water sterilizer ultraviolet water purificationuv bacteria water bottle cleaner aquarium sterilizeruv treated water purifier ultraviolet sterilizer medicalhow uv water purifier uv tool sterilizer works sterilizer for sale