Reduce Energy Consumption Condenser Tube Cleaning System

Product Description

Usage: Environmental Protection Style: Vertical Certification: SGS, ISO Specification: ISO 9001 HS Code: 8421299090 Motive Force: Electric power Performance: Descaling Equipment Trademark: peide Origin: China Condenser Tube Cleaning System

Introduction to condenser tube cleaning system

Condenser tube cleaning system is a device used to scrub the inner wall of heat transfer tubes of central air-conditioner condenser by physical method.When the central air-conditioner is in refrigeration process,the temperature of the refrigerant rises,so it must be lowered.Cooling water system is the pipeline system used for cooling down the refrigerant and the condenser is the heat-exchange device for cooling refrigerant.Cooling water flows into the condenser through the inner wall of the heat transfer tubes and then flows out.The cooling refrigerant flows through the outer wall of the heat transfer tubes and the condenser exchanges heat by heat transfer tubes,and thus cool down the refrigerant.The cooling water flows into the condenser at a low temperature and flows out at a high temperature after absorbing heat.After operating for a long time,the heat transfer tubes may have incrustation,fouling and stain sediment on inner wall,which may affect the heat transfer efficiency.Small temperature drop of the refrigerant affects the refrigeration effect, increases the load on the host of the central air-conditioner and reduces the life of it,so the inner wall of the condenser heat transfer tubes must be regularly cleaned to extend the life of it.

On-line condenser cleaning system is a kind of equipment used for automatically cleaning the inner wall of the condenser heat transfer tubes on line by physical method when the refrigerating unit is under operation.By injecting and collecting the balls,the system can clean the heat transfer tubes periodically.This system can reduce usage amount of Water Treatment chemicals,enhance refrigerating efficiency of the unit and save electric energy.

Operating principle of condenser tube cleaning system

To start with the water pump of the condenser tube cleaning system and pump the balls from the ball injector to the water inlet of the condenser with water.The balls enter the end cover of the condenser along with the circulating cooling water and get into the copper tube of the condenser randomly.Driven by the circulating cooling water,the balls move inside the copper tube to scrub the inner wall of the tube.After leaving the tube,the balls get out of the end cover of the condenser with the circulating cooling water and enters the ball collector installed on the outlet pipeline of the condenser.Ball trap in the ball collector then traps the balls,with the water flowing away through the screen.Then the balls return to the ball injector,which means a whole cleaning process is finished.The cleaning frequency and times can be set via microcomputer control program,to realize automatic on-line cleaning.

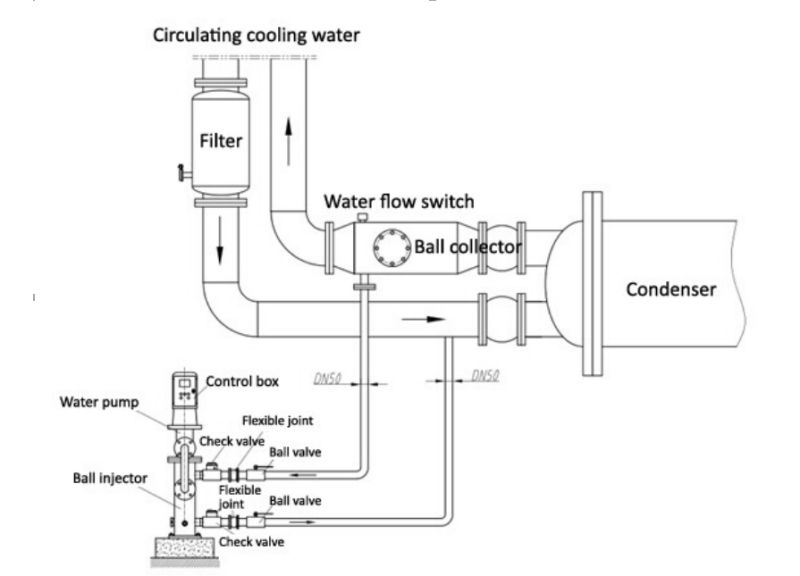

Internal schematic diagram for cleaning process

Control mode of condenser tube cleaning system

Automatic control:Set cleaning frequency and times via microcomputer control program,to realize automatic on-line cleaning.

Manual control: Manually start the condenser tube cleaning system.

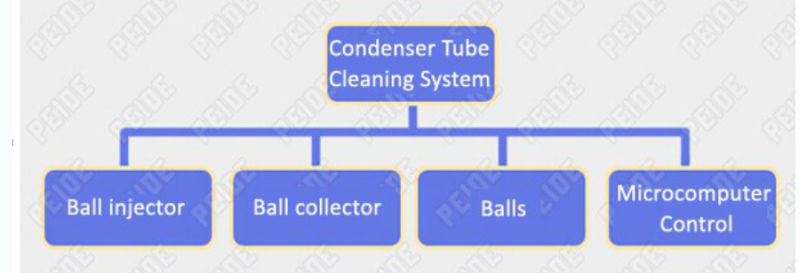

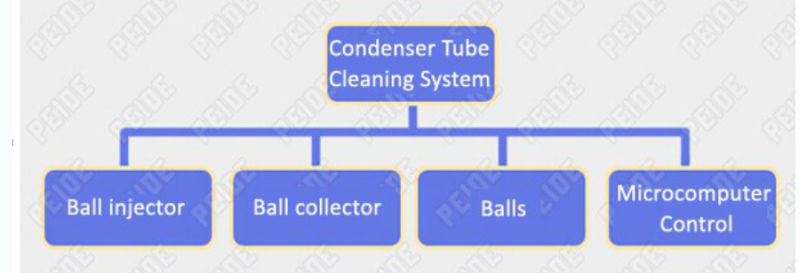

System composition of condenser tube cleaning system

Alt: system composition of condenser tube cleaning system

Ball injector:The container used for storage,injecting and collecting balls.The installation position of the ball injector and the inlet and outlet connecting pipes shall ensure that the balls are even without blockage.

Ball collector:When the balls leave the condenser,they'll be caught by the ball collector.The chamber material is carbon steel or stainless steel,the max working pressure is 10-25 bar,the effective open area is greater than 3 times of that of the connecting pipe and the hydraulic resistance loss is less than 5 Kpa.The ball collecting screen shall be designed with good hydraulic characteristics to prevent the screen from vibrating under the impact of water flow.The design of the ball collecting screen shall ensure no blocking or slipping of balls.

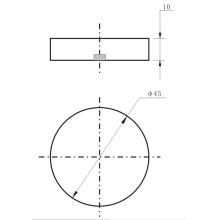

Sponge balls:Used for cleaning inner wall of the condenser heat transfer tubes.The balls shall have uniform density and good recoverability.When the balls work at a water temperature of 5-36 ºC,the diameter of wet balls shall not be larger than 0.5 mm of dry balls.During the operation,the diameter of the balls shall be 1-2 mm larger than the inner diameter of the heat transfer tubes.The balls shall remain stable during the operation to prevent the blocking of cooling water pipe.

Specification for balls and adaptive inner diameters of copper tube to be cleaned

Features of condenser tube cleaning system The host of condenser tube cleaning system integrates the water pump and ball injector,saving space and covering less area. 2. It's easy to operate.The cleaning can be finished by controlling the start and stop of the water pump by time,and the cleaning time,interval and frequency can be set.

3. The ball collector is equipped with a water flow switch.When the circulating cooling water stays still,the water pump of the cleaning device cannot rotate,which prevents the water pump from operating without water.

4. The ball collecting screen applies stainless steel screen with large mesh size,which only traps the balls and has low water resistance.

5. The balls only circulate in the pipeline and do not go through water pump,which can prevent the pump impellers from hitting the balls and extend the service life of the balls.

6. The operating cost is low and the sponge balls are the only consumables.

Specification parameters of condenser tube cleaning system Performance index: Ball collection rate ≥99% Input voltage:380V/50HZ (provide customization as required) Power: ≤4KW Requirements for working environment: Temperature ≤55ºC, relative humidity ≤95ºC Pressure loss: 0.003MPa-0.05MPa Applicable water temperature: ≤50ºC 7. Working pressure: ≤1.6MPa (customization for 2.5Mpa)

How to choose the type of condenser tube cleaning system

1.The design and selection of condenser tube cleaning system is determined by the refrigerating capacity of the chillers and the outlet pipe diameter of the cooling water.The size of balls shall be decided by the inner diameter of condenser heat transfer tubes of cold water host.

2.In order to prevent welding slags,welding rods,metal debris,sand and organic fabrics in the installation process,and the filling of cooling tower,corrosion in the cooling tubes and other foreign materials in the operation process from entering the condenser and evaporator,a less than 1.5mm precision of filter shall be installed in front of water inlet of chiller condenser (evaporator) and the effective filtering area of filter screen shall be 3 times larger than section area of the connecting pipe,to ensure proper water resistance of the filter.

Model code for condenser tube cleaning system

Specifications and models of condenser tube cleaning system

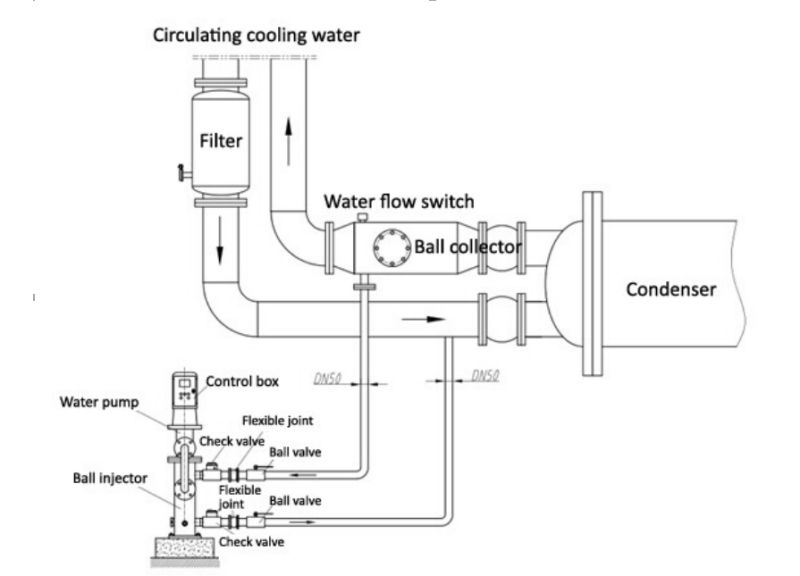

Installation diagram of condenser tube cleaning system

Precautions for Installation of condenser tube cleaning system

1.Connect the pipelines according to the pipeline system diagram and avoid incorrect connection.

2.Connect the injecting mouth of ball injector to the opening DN50 on the water inlet pipe of the condenser near the end cover,and install the DN50 ball valve on pipeline.The opening must be located behind the filter.

3.Install the ball collector on the water outlet pipe of condenser.Connect the DN50 flange outlet of ball collector to collecting mouth of ball injector and install a DN50 ball valve on pipeline.The host of condenser tube cleaning system shall be located near the condenser as much as possible.

4.The pipeline shall be simple so as to reduce the pipe bending and pipe length.

5.To ensure there is no welding slag,scrap iron or other things in the pipe from the injecting point on water inlet pipe of condenser to collecting point of ball collector or the end cover of condenser, so that the balls can clean the heat transfer tubes without being blocked or scratched by foreign materials.It is suggested to install the filter in front of injecting point on the water inlet pipe of the condenser.

6.Reserve a maintenance space of 0.6 m around the host of condenser tube cleaning system. Connect the water flow switch and the electrically operated valve of the filter according to the number.The control box applies a power supply of 380V/50Hz.Notice that the rotation arrow of water pump shall be consistent with that of water pump identification.

Contact us if you need more details on Water Treatment. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Consumption Condenser Tube Cleaning System、Water Treatment Equipment. If these products fail to match your need, please contact us and we would like to provide relevant information.

Introduction to condenser tube cleaning system

Condenser tube cleaning system is a device used to scrub the inner wall of heat transfer tubes of central air-conditioner condenser by physical method.When the central air-conditioner is in refrigeration process,the temperature of the refrigerant rises,so it must be lowered.Cooling water system is the pipeline system used for cooling down the refrigerant and the condenser is the heat-exchange device for cooling refrigerant.Cooling water flows into the condenser through the inner wall of the heat transfer tubes and then flows out.The cooling refrigerant flows through the outer wall of the heat transfer tubes and the condenser exchanges heat by heat transfer tubes,and thus cool down the refrigerant.The cooling water flows into the condenser at a low temperature and flows out at a high temperature after absorbing heat.After operating for a long time,the heat transfer tubes may have incrustation,fouling and stain sediment on inner wall,which may affect the heat transfer efficiency.Small temperature drop of the refrigerant affects the refrigeration effect, increases the load on the host of the central air-conditioner and reduces the life of it,so the inner wall of the condenser heat transfer tubes must be regularly cleaned to extend the life of it.

On-line condenser cleaning system is a kind of equipment used for automatically cleaning the inner wall of the condenser heat transfer tubes on line by physical method when the refrigerating unit is under operation.By injecting and collecting the balls,the system can clean the heat transfer tubes periodically.This system can reduce usage amount of Water Treatment chemicals,enhance refrigerating efficiency of the unit and save electric energy.

Operating principle of condenser tube cleaning system

To start with the water pump of the condenser tube cleaning system and pump the balls from the ball injector to the water inlet of the condenser with water.The balls enter the end cover of the condenser along with the circulating cooling water and get into the copper tube of the condenser randomly.Driven by the circulating cooling water,the balls move inside the copper tube to scrub the inner wall of the tube.After leaving the tube,the balls get out of the end cover of the condenser with the circulating cooling water and enters the ball collector installed on the outlet pipeline of the condenser.Ball trap in the ball collector then traps the balls,with the water flowing away through the screen.Then the balls return to the ball injector,which means a whole cleaning process is finished.The cleaning frequency and times can be set via microcomputer control program,to realize automatic on-line cleaning.

Internal schematic diagram for cleaning process

Control mode of condenser tube cleaning system

Automatic control:Set cleaning frequency and times via microcomputer control program,to realize automatic on-line cleaning.

Manual control: Manually start the condenser tube cleaning system.

System composition of condenser tube cleaning system

Alt: system composition of condenser tube cleaning system

Ball injector:The container used for storage,injecting and collecting balls.The installation position of the ball injector and the inlet and outlet connecting pipes shall ensure that the balls are even without blockage.

Ball collector:When the balls leave the condenser,they'll be caught by the ball collector.The chamber material is carbon steel or stainless steel,the max working pressure is 10-25 bar,the effective open area is greater than 3 times of that of the connecting pipe and the hydraulic resistance loss is less than 5 Kpa.The ball collecting screen shall be designed with good hydraulic characteristics to prevent the screen from vibrating under the impact of water flow.The design of the ball collecting screen shall ensure no blocking or slipping of balls.

Sponge balls:Used for cleaning inner wall of the condenser heat transfer tubes.The balls shall have uniform density and good recoverability.When the balls work at a water temperature of 5-36 ºC,the diameter of wet balls shall not be larger than 0.5 mm of dry balls.During the operation,the diameter of the balls shall be 1-2 mm larger than the inner diameter of the heat transfer tubes.The balls shall remain stable during the operation to prevent the blocking of cooling water pipe.

Specification for balls and adaptive inner diameters of copper tube to be cleaned

| Inner diameters of copper tube (mm) | 16 | 17 | 18 | 19 | 20 | 21 | 22 | 23 | 24 | 25 |

| Diameters of balls (mm) | 17 | 18 | 19 | 20 | 21 | 22 | 23 | 24 | 25 | 26 |

Features of condenser tube cleaning system The host of condenser tube cleaning system integrates the water pump and ball injector,saving space and covering less area. 2. It's easy to operate.The cleaning can be finished by controlling the start and stop of the water pump by time,and the cleaning time,interval and frequency can be set.

3. The ball collector is equipped with a water flow switch.When the circulating cooling water stays still,the water pump of the cleaning device cannot rotate,which prevents the water pump from operating without water.

4. The ball collecting screen applies stainless steel screen with large mesh size,which only traps the balls and has low water resistance.

5. The balls only circulate in the pipeline and do not go through water pump,which can prevent the pump impellers from hitting the balls and extend the service life of the balls.

6. The operating cost is low and the sponge balls are the only consumables.

Specification parameters of condenser tube cleaning system Performance index: Ball collection rate ≥99% Input voltage:380V/50HZ (provide customization as required) Power: ≤4KW Requirements for working environment: Temperature ≤55ºC, relative humidity ≤95ºC Pressure loss: 0.003MPa-0.05MPa Applicable water temperature: ≤50ºC 7. Working pressure: ≤1.6MPa (customization for 2.5Mpa)

How to choose the type of condenser tube cleaning system

1.The design and selection of condenser tube cleaning system is determined by the refrigerating capacity of the chillers and the outlet pipe diameter of the cooling water.The size of balls shall be decided by the inner diameter of condenser heat transfer tubes of cold water host.

2.In order to prevent welding slags,welding rods,metal debris,sand and organic fabrics in the installation process,and the filling of cooling tower,corrosion in the cooling tubes and other foreign materials in the operation process from entering the condenser and evaporator,a less than 1.5mm precision of filter shall be installed in front of water inlet of chiller condenser (evaporator) and the effective filtering area of filter screen shall be 3 times larger than section area of the connecting pipe,to ensure proper water resistance of the filter.

Model code for condenser tube cleaning system

Specifications and models of condenser tube cleaning system

| No. | Model | Selection guide, subject to actual cooling water pipe diameter |

| 1 | CTCS-150-N-1.6 | General host under 200 RT |

| 2 | CTCS-200-N-1.6 | General host between 200-500 RT |

| 3 | CTCS-250-N-1.6 | General host between 300-500 RT |

| 4 | CTCS-300-N-1.6 | General host between 500-800 RT |

| 5 | CTCS-350-N-1.6 | General host between 600-1000 RT |

| 6 | CTCS-400-N-1.6 | General host between 1000-1500 RT |

| 7 | CTCS-450-N-1.6 | General host above 1500 RT |

Installation diagram of condenser tube cleaning system

Precautions for Installation of condenser tube cleaning system

1.Connect the pipelines according to the pipeline system diagram and avoid incorrect connection.

2.Connect the injecting mouth of ball injector to the opening DN50 on the water inlet pipe of the condenser near the end cover,and install the DN50 ball valve on pipeline.The opening must be located behind the filter.

3.Install the ball collector on the water outlet pipe of condenser.Connect the DN50 flange outlet of ball collector to collecting mouth of ball injector and install a DN50 ball valve on pipeline.The host of condenser tube cleaning system shall be located near the condenser as much as possible.

4.The pipeline shall be simple so as to reduce the pipe bending and pipe length.

5.To ensure there is no welding slag,scrap iron or other things in the pipe from the injecting point on water inlet pipe of condenser to collecting point of ball collector or the end cover of condenser, so that the balls can clean the heat transfer tubes without being blocked or scratched by foreign materials.It is suggested to install the filter in front of injecting point on the water inlet pipe of the condenser.

6.Reserve a maintenance space of 0.6 m around the host of condenser tube cleaning system. Connect the water flow switch and the electrically operated valve of the filter according to the number.The control box applies a power supply of 380V/50Hz.Notice that the rotation arrow of water pump shall be consistent with that of water pump identification.

Contact us if you need more details on Water Treatment. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Consumption Condenser Tube Cleaning System、Water Treatment Equipment. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Descaling Equipment > Others Descaling Equipment

Premium Related Products

Other Products

Hot Products

oil-water juice water uv container price listuv plant disinfection system for waste water low priceUVC stainless steel disinfection machine best buywaste water treatment ozone generator stainless steel filter housing price liststeel cartridge automatic backwash filter254nm SS 304/316 UV sterilizer for food processmytest mini modernhome use water molten salt furnace for distillationBest Seller Suppliers antique bulk distilled waterantique dental water distiller best priceultraviolet sterilizer for water uv water disinfection systems uv technology for water purificationuv light water filter ultraviolet sterilizer uv light water purificationfish tank sterilizer ultraviolet light for wateruv water sterilizer ultraviolet water purificationuv bacteria water bottle cleaner aquarium sterilizeruv treated water purifier ultraviolet sterilizer medicalhow uv water purifier uv tool sterilizer works sterilizer for sale