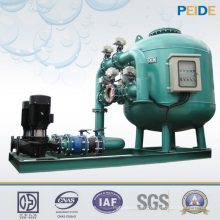

Water Treatment Equipment Service Supply Manufacturer for HVAC System

Basic Info

Model No.: PD

Product Description

Model NO.: PD Motive Force: Electric power Performance: Efficient Filtration Water Flow Rate: 3.7---305t/H Backwash Duration: 20-50min Specification: ISO 9001 HS Code: 8421219990 Usage: Environmental Protection Style: Vertical Certification: SGS, ISO Filtration Speed: 25-35m/H Trademark: peide Origin: China Water Treatment Equipment Service Supply Manufacturer for HVAC System

Fiber ball filter are used in average accuracy filtering to remove suspended matters

in water because of big ratio surface area and gaprate and flexibility and corrosion resisting capabilities.

It is widely used in living water supply,water injection in oil field, fine filtering in chemical liquor,

demineralization and desalination of industry water and pretreatment of pure water,

second-class treatment inlight industry and paper making industry.

Working Principle

Fiber ball filter with its great surface area and porosity of suspended particles that touch the unifying role of

tensile, adhesion of particles are suspended in water, the closure in the filter layer, because the filter was flexible,variable porosity in the filtration process , the filter bed cross-sectional and longitudinal uniformity of the porosity gradient to ensure a reasonable high-speed filtering and high-precision filters can be achieved simultaneously During operation, water flow into the upper and flow out in bottom. Under the action of gravity,the self-service fiber density adjustment means pushing fiber filter bed running down the fiber filter layer is compressed, its bulk density gradually increased along the flow direction,

so that the filter layer along the water flow porosity direction by large became smaller, the corresponding filter pore diameter and pore decreases, there by forming a particularly desirable variable void deep filter status.

Its filtration process has both horizontal and depth filtration,

as well as vertical depth filtration, thus effectively improving the filtering accuracy.

During backwash, clean water in the opposite direction through the fiber filter bed, in the backwash water and

clean air role, self-service fiber density, fiber filter bed adjusting device driven by the upward movement of the

fiber filter upward extension to reach a loose state, by mixing air and water cleaning technology, and everything in the bubble and water washing process, the fiber filter longitudinally in a constant state of jitter, thereby making fiber filter cleaned very thoroughly, so as to achieve the desired cleaning effection.

Characteristics

1. High efficiency of filtration: the filter filament diameter up to tens of microns to a few microns, with a huge

surface area,its removal rate for SS was close to 100%.

Suspended solids content of SS: 20mg / L, the filtered effluent suspended solids less than 2mg / L;

Particle size greater than 5μm suspended solids: removal rate is up to 90-95%.

Also can remove Bacteria, viruses, organic molecules, colloids, iron and other impurities.

2.Stepless variable gap filter layer: automatic form the filter bed porosity,no need to allocate artifically.

3.Stable performance, long service life:

Filaments after modification, the performance does not decay, with strong chemical stability, filter life is

generally up to 5--10 years;

Have sufficient chemical stability, no harmful ingredients elution, filtration, high performance polypropylene

fiber filament light texture, strength,

Good elasticity, wear resistance, corrosion resistance, non-absorbent.

4.Reasonable structure: floating slab without jamming: original guide,

to ensure that the floating plate does not appear skewed jamming; automatic adjustment.

The density of the entire filter layer: filter layer density automatically match process, without power;

filter cleaning when fully discharged loose, and can be used to scrub the air of high intensity,

clean thoroughly, filter layer does not harden.

5.Filter speed: 20-50m/h

6.Interception capacity: generally 5-15kg / m3 filter is 2-3 times that of conventional filters.

7.Small footprint: manufactured in the same amount of water, covering only the traditional filter of 1/3-1/8.

8.Tons of low cost: the system take the same amount of water, cost less than conventional filters.

9.Low water consumption: only 1-3% of the water cycle system, backwash generally available raw water.

Application

Swimming Pool

Artificial landscape

Drinking Water

Pretreatment for RO

Industrial Process Water Supply

Power Station Water Supply

Boiler Feed Water

Circulating Cooling System

Air Conditioning Cooling Water

Seawater Desalination Plant

Oilfield reinjection water

Gray water Reuse

Sewage Treatment

Wastewater Treatment

Technical Data

1.Treatment effect

influent suspended solids: Contact us if you need more details on Industrial water filter. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Water Treatment、Industrial Water Filter Systems. If these products fail to match your need, please contact us and we would like to provide relevant information.

Fiber ball filter are used in average accuracy filtering to remove suspended matters

in water because of big ratio surface area and gaprate and flexibility and corrosion resisting capabilities.

It is widely used in living water supply,water injection in oil field, fine filtering in chemical liquor,

demineralization and desalination of industry water and pretreatment of pure water,

second-class treatment inlight industry and paper making industry.

Working Principle

Fiber ball filter with its great surface area and porosity of suspended particles that touch the unifying role of

tensile, adhesion of particles are suspended in water, the closure in the filter layer, because the filter was flexible,variable porosity in the filtration process , the filter bed cross-sectional and longitudinal uniformity of the porosity gradient to ensure a reasonable high-speed filtering and high-precision filters can be achieved simultaneously During operation, water flow into the upper and flow out in bottom. Under the action of gravity,the self-service fiber density adjustment means pushing fiber filter bed running down the fiber filter layer is compressed, its bulk density gradually increased along the flow direction,

so that the filter layer along the water flow porosity direction by large became smaller, the corresponding filter pore diameter and pore decreases, there by forming a particularly desirable variable void deep filter status.

Its filtration process has both horizontal and depth filtration,

as well as vertical depth filtration, thus effectively improving the filtering accuracy.

During backwash, clean water in the opposite direction through the fiber filter bed, in the backwash water and

clean air role, self-service fiber density, fiber filter bed adjusting device driven by the upward movement of the

fiber filter upward extension to reach a loose state, by mixing air and water cleaning technology, and everything in the bubble and water washing process, the fiber filter longitudinally in a constant state of jitter, thereby making fiber filter cleaned very thoroughly, so as to achieve the desired cleaning effection.

Characteristics

1. High efficiency of filtration: the filter filament diameter up to tens of microns to a few microns, with a huge

surface area,its removal rate for SS was close to 100%.

Suspended solids content of SS: 20mg / L, the filtered effluent suspended solids less than 2mg / L;

Particle size greater than 5μm suspended solids: removal rate is up to 90-95%.

Also can remove Bacteria, viruses, organic molecules, colloids, iron and other impurities.

2.Stepless variable gap filter layer: automatic form the filter bed porosity,no need to allocate artifically.

3.Stable performance, long service life:

Filaments after modification, the performance does not decay, with strong chemical stability, filter life is

generally up to 5--10 years;

Have sufficient chemical stability, no harmful ingredients elution, filtration, high performance polypropylene

fiber filament light texture, strength,

Good elasticity, wear resistance, corrosion resistance, non-absorbent.

4.Reasonable structure: floating slab without jamming: original guide,

to ensure that the floating plate does not appear skewed jamming; automatic adjustment.

The density of the entire filter layer: filter layer density automatically match process, without power;

filter cleaning when fully discharged loose, and can be used to scrub the air of high intensity,

clean thoroughly, filter layer does not harden.

5.Filter speed: 20-50m/h

6.Interception capacity: generally 5-15kg / m3 filter is 2-3 times that of conventional filters.

7.Small footprint: manufactured in the same amount of water, covering only the traditional filter of 1/3-1/8.

8.Tons of low cost: the system take the same amount of water, cost less than conventional filters.

9.Low water consumption: only 1-3% of the water cycle system, backwash generally available raw water.

Application

Swimming Pool

Artificial landscape

Drinking Water

Pretreatment for RO

Industrial Process Water Supply

Power Station Water Supply

Boiler Feed Water

Circulating Cooling System

Air Conditioning Cooling Water

Seawater Desalination Plant

Oilfield reinjection water

Gray water Reuse

Sewage Treatment

Wastewater Treatment

Technical Data

1.Treatment effect

influent suspended solids: Contact us if you need more details on Industrial water filter. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Water Treatment、Industrial Water Filter Systems. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : HVAC System

Premium Related Products

Other Products

Hot Products

oil-water juice water uv container price listuv plant disinfection system for waste water low priceUVC stainless steel disinfection machine best buywaste water treatment ozone generator stainless steel filter housing price liststeel cartridge automatic backwash filter254nm SS 304/316 UV sterilizer for food processmytest mini modernhome use water molten salt furnace for distillationBest Seller Suppliers antique bulk distilled waterantique dental water distiller best priceultraviolet sterilizer for water uv water disinfection systems uv technology for water purificationuv light water filter ultraviolet sterilizer uv light water purificationfish tank sterilizer ultraviolet light for wateruv water sterilizer ultraviolet water purificationuv bacteria water bottle cleaner aquarium sterilizeruv treated water purifier ultraviolet sterilizer medicalhow uv water purifier uv tool sterilizer works sterilizer for sale