Bespoke Chemical Dosing System for Chilled Water

Basic Info

Model No.: XQ

Product Description

Working Principle

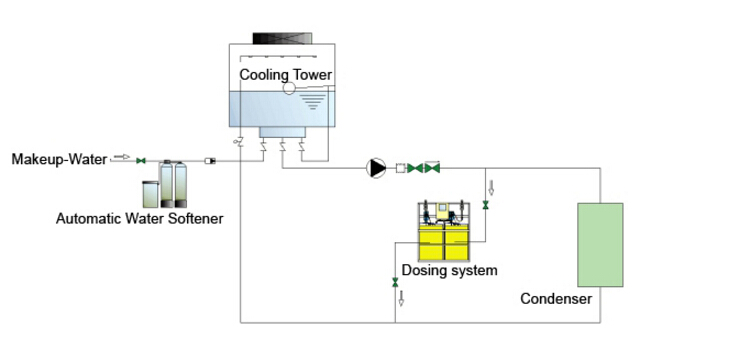

Technological Process of Chemical dosing systems

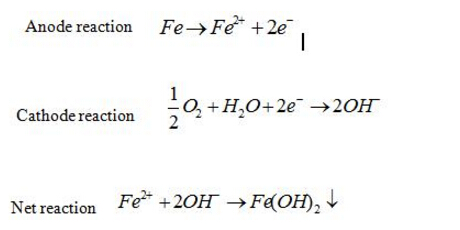

III. Classification of chemical agent of Cooling tower Dosing System 3.1 Corrosion Inhibitors for Cooling Water Chemical Treatment has a comprehensive portfolio of organic, inorganic, and non-phosphate corrosion inhibitors engineered to passivate metals by reducing the corrosion potential associated with the anode and cathode of the corrosion cell. Chemicals that form protective films at the anode include chromate, orthophosphate, nitrite, silicate, and molybdate. Chemicals that form films on the cathode include calcium carbonate, polyphosphate, zinc, phosphonate, and azoles. We have a selection of organics that are both anodic and cathodic inhibitors. 3.2 Scale/Deposition Control ChemTreat's chemical product lines to control deposition and fouling consist of two major classes of dispersants. Polymers prevent, or reverse, the growth of mineral deposits, while surfactants, or surface-active agents, render particles less adherent and more easily dispersed. 3.3 Biological Control Our biological control programs are customized by your field engineer to produce the best organism kill-rate with chemicals from our complete portfolio of biocides, including oxidizing and non-oxidizing biocides, cell wall and cytoplasm toxicants, and enzyme poisons. III. Monitoring and control of Dosing systems in circulating cooling water 4.1 Interconnected control of PH value on-line detection and acid adding 4.2 Interconnected control of conductivity on-line detection and discharge capacity 4.3 Interconnected control of ORP on-line detection and oxidative fungicide 4.4 Interconnected control of concentration on-line detection and dosing quantity of scaling-corrosion inhibitor Application of Dosing systems in the chilled water system I. Common problems of chilled water system As the water quantity of the chilled water system remains almost the same and the calcium and magnesium in the water will not increase due to the circulation, so its trend structure is not so serious. The problem of the system mainly lies in the dissolved oxygen corrosion because of the microcell formed by the carbon steel in the water. The process of corrosion reaction can be expressed as:

Ferric hydroxide is quite easy to be oxidized into red brown rust and this is the main reason for red water in the chilled water. In the open-type and spray-type chilled water system, as part of the system exposes to air or directly contact with air, the dissolved oxygen content in the system is very sufficient; while in the closed-type chilled water system, the dissolved oxygen will become insufficient due to the consumption caused by corrosion. Despite of this, there is still some dissolved oxygen left in the system, mainly coming through the valve, pipe joint and thrust pad of pump. Besides, though the chilled water system is seldom supplemented with water, the dissolved oxygen will also be added into the system with the supplementary water. Therefore, the dissolved oxygen is the main reason which causes the corrosion of chilled water system. As the chilled water system runs in a closed circulation for a long time, it will lead to the propagation of anaerobic bacteria which can also corrupt the pipe. Dimension parameter data table for the dosing systems

Ferric hydroxide is quite easy to be oxidized into red brown rust and this is the main reason for red water in the chilled water. In the open-type and spray-type chilled water system, as part of the system exposes to air or directly contact with air, the dissolved oxygen content in the system is very sufficient; while in the closed-type chilled water system, the dissolved oxygen will become insufficient due to the consumption caused by corrosion. Despite of this, there is still some dissolved oxygen left in the system, mainly coming through the valve, pipe joint and thrust pad of pump. Besides, though the chilled water system is seldom supplemented with water, the dissolved oxygen will also be added into the system with the supplementary water. Therefore, the dissolved oxygen is the main reason which causes the corrosion of chilled water system. As the chilled water system runs in a closed circulation for a long time, it will lead to the propagation of anaerobic bacteria which can also corrupt the pipe. Dimension parameter data table for the dosing systems Type | Volume of chemical tank | Dimension | Flow rate of circulating water | ||

L | Length(L) | Width(L) | height(L) | m3/h | |

One tank with One pump | 100 | 550 | 550 | 1250 | no more than 300 |

One tank with One pump | 200 | 650 | 650 | 1440 | no more than 5000 |

One tank with One pump | 500 | 910 | 910 | 1650 | no more than 20000 |

One tank with One pump | 1000 | 1140 | 1150 | 1800 | no more than 30000 |

Two tank with Two pump | 200 | 1250 | 650 | 1440 | no more than 5000 |

Two tank with Two pump | 500 | 1770 | 910 | 1650 | no more than 20000 |

Two tank with Two pump | 1000 | 2250 | 1150 | 1800 | no more than 30000 |

Three tank with Three pump | 200 | 1250 | 650 | 1440 | no more than 5000 |

Three tank with Three pump | 500 | 1770 | 910 | 1650 | no more than 20000 |

Three tank with Three pump | 1000 | 2250 | 1150 | 1800 | no more than 30000 |

Three tank with Three pump | 200 | 1850 | 650 | 1440 | no more than 5000 |

Three tank with Three pump | 500 | 2630 | 910 | 1650 | no more than 20000 |

Three tank with Three pump | 1000 | 3350 | 1150 | 1800 | no more than 30000 |

Packing

FAQ Do you have certificates? Yes , we have ISO certificate and certificate of patent Do you have design team? We have a professional design team provide drawings, we wait for your confirmation and production Can you guarantee delivery time ? Timely transport, ensure the delivery time Are you maufacturer ? Yes, we are the professional Water Treatment Equipment manufacturer in china Contact us if you need more details on Dosing System. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Dosing Pumps、Chemical Metering Pumps. If these products fail to match your need, please contact us and we would like to provide relevant information.

FAQ Do you have certificates? Yes , we have ISO certificate and certificate of patent Do you have design team? We have a professional design team provide drawings, we wait for your confirmation and production Can you guarantee delivery time ? Timely transport, ensure the delivery time Are you maufacturer ? Yes, we are the professional Water Treatment Equipment manufacturer in china Contact us if you need more details on Dosing System. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Dosing Pumps、Chemical Metering Pumps. If these products fail to match your need, please contact us and we would like to provide relevant information. Product Categories : Soft water series